MTP Gold Medal Winners – ITM Industry Europe 2019

The Gold Medal is not only an award, it is a recommendation of experts for the presented products and a promotion strategy, which starts at events organised by the MTP Group. This years’ edition 16 products from ITM Poland fair have been awarded, and one product from 3D Solutions Fair.

EVO HAEUSLER 4-roll metal sheet rolling mill

HAEUSLER AG, Duggingen, Szwajcaria

HEG sp. z o.o., sp.k. Szczecin

Pavilion 5, stand 39

HAEUSLER EVO is a revolutionary new 4-roll metal sheet rolling mill equipped with the patented VSA® guidance variable planetary system, the most advanced in the market CNC BENDtronic® control system and unmatched HAEUSLER HHDS® hybrid drive unit. Thanks to the solutions used, EVO rolling mills combine EVO lower Total Cost of Ownership with the highest productivity, reliability and unparalleled ease of use for the operator.

AMB – Fibre laser with adjustable beam profile

IPG Laser GmbH, Burbach, Niemcy

IPG PHOTONICS Sp. z o.o., Gliwice

Pavilion 5, stand 13

YLS-15000-AMB fibre laser with adjustable beam profile with a power output of 15 kW allows you to dynamically change the output beam mode and increase flexibility in cutting and welding applications. AMB enables you to adjust the output beam mode in any combination from a central beam of high power density to an outer ring-shaped beam. AMB allows you to treat a broader range of material thickness and improve the quality of punching and cutting, as well as to optimize the efficiency of welding. eRS Cloud

POWER-TECH Janusz Marcin Ejma,Wałcz

Pavilion 5, stand 59

eRS Cloud – a modern reporting system offering unlimited possibilities for creating dynamic reports. The system based on the latest software solutions allows you to create any graphical reports, and dynamic and static data presentation. Export of forms to popular formats (PDF, JPG, Excel) and further analysis, for example in Excell.

T REX 800 pipe bender

STAR TECHNOLOGY S.R.L.

DIG ŚWITAŁA Sp. z o.o.

Pavilion 5, stand 29

Star technology – an Italian manufacturer dealing with the manufacture of pipe benders for 40 years. They are the most precise benders in the world; in addition, they are safe and environmentally friendly. They work quietly but efficiently, making the operator’s work less demanding.

Laser Ensis 3015 6KW Gen3

AMADA Sp. z o.o., Liszki

Pavilion 5, stand 6

ENSIS 6 kW uses vario beam control and auto collimation unit developed by AMADA, as well as the silk cut system; it can cut black steel and stainless steel with the quality comparable to a CO2 laser. The scope of the cut material is 25mm black steel, 25mm stainless steel, 25mm aluminium, 12mm copper, 15mm brass.

Mitutoyo MiCAT Planner software

Mitutoyo Polska Sp. z o.o., Wrocław

Pavilion 5A, stand 15

MiCAT Planner software is a new product in the Mitutoyo portfolio. It is a response to the market need for rapid implementation to the production of new components, where quality control of the components made based on 3D measurements using the CMM machine is an important element. The 3D CAD model obtained at the designing stage is loaded into the MiCAT Planner, where an optimized measurement program is generated. Such an approach is a significant improvement in the implementation of new quality control elements, in contrast to the classical approach based on 2D technical drawings.

Mitutoyo MiCAT Planner software

Mitutoyo Polska Sp. z o.o., Wrocław

Pavilion 5A, stand 15

Innovative guillotine shears of the ELECTRO-CUT series is a breakthrough solution for effective and energy-efficient cutting of metal sheet. The innovative solutions used in the ELECTRO-CUT series consist in the combination of rolling-belt systems, modern AC servomotors and a special transmitting shaft evenly distributing the cutting force over the entire length of the upper knife. As a result, higher cutting efficiency is obtained while saving energy up to 50% compared to traditional hydraulic solutions.

SMOOTH Monitor AX – software for monitoring and analysing machine tool data in real time

YAMAZAKI MAZAK CENTRAL EUROPE Sp. z o.o. Oddział w Polsce, Katowice

Pavilion 3A, stand 14

MAZAK and Industry 4.0 The emphasis on increased productivity, quality and providing customers with more and more information, from machine utilization rates to three-dimensional simulation of 5-axis programs, is already being felt throughout the supply chain, even in the smallest mechanical workshops. That is why Mazak has developed the SMOOTH technology — a CNC solution able to implement in practice the ideas of Industry 4.0, i.e. provide communication, productivity and data analysis tools in every factory and workshop. SMOOTH technology can act as a catalyst for the implementation of the principles of Industry 4.0. Its key aspect is the ability to collect and analyse data, and thereby help production and management teams in making quick informed decisions which will translate into greater production efficiency and speed. What is particularly important is the fact that the SMOOTH technology is fully scalable. As the production grows and new machines and automation systems are implemented, it can be quickly adapted to the new requirements. In a plant operating according to the concept of Industry 4.0, all aspects of production are integrated, monitored and analysed — from planning, virtual simulation of details to be processed, energy consumption, tool management to maintenance. The objective is to achieve greater efficiency and higher quality of products while minimizing downtime. One of the tools to implement the idea of Industry 4.0 is SMOOTH Monitor AX..

ES5 robotized stations with a drawer storage system for CNC machines

EasyRobots Sp. z o.o.

Pavilion 6, stand 48

The robotic arm over the drawer storage system reduces the working area, and the use of two grippers enables simultaneous reception and loading of elements, minimizing the time required for processing. 4 drawers equipped with replaceable profiled trays enable easy elements refilling. The process does not require stopping the work of the robot or the machine, and the employee does not have to supervise the devices until refilling is required.

ConnECKt 4.0 System

ECKERT AS Sp. z o.o., Legnica

Pavilion 5, stand 44

The intelligent ConnECKt 4.0 Ready system by Eckert is a product designed for companies that want to be one step ahead and are ready to enter into the reality of Industry 4.0. Production management with ConnECKt 4.0 Ready is easier than ever before thanks to the constant monitoring of the most important process parameters. Current data and predefined reports and analyses are available anywhere in the world and they can be easily verified from the level of a specially designed panel.

Mitutoyo FORMTRACER Avant system for contour and coarseness measurements

Mitutoyo Polska Sp. z o.o., Wrocław

Pavilion 5A, stand 15

The Mitutoyo FORMTRACER Avant measuring system is a new product in the Mitutoyo portfolio. This measurement solution addresses the needs of a highly accurate method of checking surface contours and coarseness. The measuring head quick change system enables efficient geometrical (macro scale) and surface coarseness (micro scale) measurements. Such a configuration allows you to avoid the fundamental limitation in the (single head) integrated systems, which is the shape of the probes and the change in measurement accuracy with a measured range..

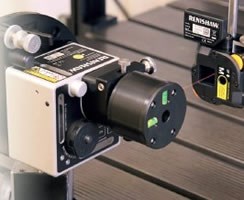

XK10 laser system for measuring geometric errors

RENISHAW Sp. z o.o., Warszawa

Pavilion 3A, stand 30

The new XK10 laser system by Renishaw eliminates the disadvantages associated with the use of traditional material patterns. Now, using one system, you can set many types of CNC machine tools. More information about Renishaw products for calibration and machine tools performance monitoring can be found at www.renishaw.pl/calibration.

CLX 450 Lathe Tokarka CLX 450

FAMOT Pleszew Sp. z o.o., Pleszew

DMG MORI Polska Sp. z o.o., Pleszew

Pavilion 3, stand 2

One of the currents of Industry 4.0 concept (i.e. 4th industrial revolution) is the automation of manufacturing processes. High functionality of CLX 450 V6 – a CNC turning machine, combined with Robo2Go automation system, provides an ideal solution for medium and high volume production. Using CLX 450 V6 lathe with Robo2Go loading system guarantees a stable and reliable operation, as well as fast return on invested funds.

2D TruLaser 5030 fiber 10 kW laser cutter

TRUMPF POLSKA Spółka z o.o. Sp.k.

Pavilion 5, stand 71

10 kW resonator in the new generation of the 10 kW 2D TruLaser 5030 fiber laser cutter – as an absolute new product of the TRUMPF company: a. Laser driven by a dual-core fibre optic cable; b. LED modules with passive cooling, the so-called LED stacks; c. Quick Plug & Play replacement of modules; d. Comfortable connecting and disconnecting the fibre thanks to Plug & Play connections; e. Real-time measurement of power output from resonators; f. Stability of the power generated by the laser resonator is +/-1% throughout the lifetime of the laser; g. Resonator’s resistance to damage caused by the radius reflected from the workpiece.

Eagle iNspire 1530 F15.0 laser cutter equipped with the eVa laser head

POWER-TECH Janusz Marcin Ejma, Wałcz

Pavilion 5, stand 59

The iNspire laser cutter with a 15 kW laser source is a technologically advanced, precise and dynamic device dedicated to demanding mass production. The machine achieves the cutting speed of 150m/min and the acceleration of 6G. As a standard, it is equipped with a Fiber laser source, linear motors in all axes, body made of a composite material, carbon fibre crosshead, dynamic pallet changer.

FiberCut 1530 fibre cutter

SERON Kołodziejczyk Sp.j.

Pavilion 5, stand 2

FiberCut fibre cutters by Seron are innovative, energy-efficient machines designed for fast cutting of all kinds of metal sheet. They are characterized by excellent reproducibility and precision, providing the highest quality of details. The lasers are equipped with a real-time control system with Ethernet connection, which guarantees remote service and operator access. The innovations applied, e.g. laser beam autofocusing or consistency with Industry 4.0, guarantee the optimization of production processes.

ATO LAB Atomizer

3D Lab sp. z o.o., Warszawa

Pavilion 6, stand 7

3D Lab sp. is a manufacturer of laboratory atomizers for the production of metal powders – ATO LAB. It is the world’s first compact solution for ultrasound powdering of metal. The device is dedicated to the needs of incremental technologies, hot isostatic pressing and traditional powder metallurgy. ATO LAB atomizer significantly streamlines the process of implementation of new metal powders in 3D printing.