Gold Medal ITM 2021- we know the winners!

As many as 11 products were favored by the Competition Jury and won the MTP Gold Medal at ITM INDUSTRY EUROPE 2021. This prestigious award can also be proud of one of the exhibitors at MODERNLOG fair. It will be loud about these winners. They set new standards.

The Gold Medal is not only an award, it is a recommendation of experts for the presented products and a promotion strategy, which starts at events organised by the MTP Group. This years’ edition 11 products from ITM INDUSTRY FAIR and one from Modernlog fair have been awarded.

ITM INDUSTRY EUROPE 2021

Factory 2.0 NET

OMNI3D Sp. z o.o.

The latest printer Factory 2.0 NET is designed for professional industrial applications. The machine is distinguished by: large working surface (500x500x570mm), closed, insulated and actively heated working chamber, high dimensional precision, automatic table calibration and the possibility of printing with the use of 2 extruders. Extrusion system, pressure control, specially developed air circulation (Omni Cooling System) are the features that distinguish it from other 3D printers. The use of the Omni Auto Head Calibration System allows for maintenance-free machine calibration, while Omni Web Control allows for remote viewing of the 3D printing process and remote machine management from the website.

Sorting Guide feature

TRUMPF POLSKA Spółka z ograniczoną odpowiedzialnością Sp.k.

Nowadays, you are under constant time pressure in sheet metal processing: at the interface between manual tasks and machine processing processes often lack transparency and orderliness. Wouldn’t it be great to save time on manual sorting − thus increasing the uptime of the machine? The new Sorting Guide feature: helps the operator to remove and sort workpieces. In addition, it selects workpieces on the screen by colour-coding them in order, according to sequential processes or geometry. The removed parts are automatically posted. In this way, mistakes are avoided − and this means time savings and higher quality of work. Discover the extremely intelligent assistant for sheet metal processing.

Innovative tools for forestry machinery with a modified casting work surface

Consortium:

Łukasiewicz Research Network – Krakow Institute of Technology (Leader)

Łukasiewicz Research Network – Industrial Institute of Agricultural Engineering

Specodlew Sp. z o.o.

The implementation of new working elements developed under the project is an opportunity for the commercial partner of the project to gain an economic and technological advantage over domestic competitors, and above all on the global market of forestry tools. Cooperation between the company P.I.O. SPECODLEW and research units, within the Consortium created, eliminated the barrier limiting the implementation of costly technologies in order to offer economically justified technological solutions.

Innovative pro-ecological furfuryl resins Żyfur EKO® dedicated to the foundry industry

Consortium:

Łukasiewicz Research Network – Krakow Institute of Technology (Leader)

Grupa Azoty Jednostka Ratownictwa Chemicznego sp. z o.o. (Consortium member, Resin producer)

Prec-Odlew sp. z o.o. (Consortium member)

The Żywfur EKO® series are innovative, pro-ecological furfuryl resins used as a binder for the preparation of self-curing moulding masses, hardened with the “no bake” method. The Żywfur EKO® resins are intended for the preparation of moulding and core masses with the possibility of using regenerated mass for iron castings. The implementation of Żywfur EKO® products reduces the emissions of furfuryl alcohol and formaldehyde in the processes of forming, cleaning, knocking out and pouring castings.

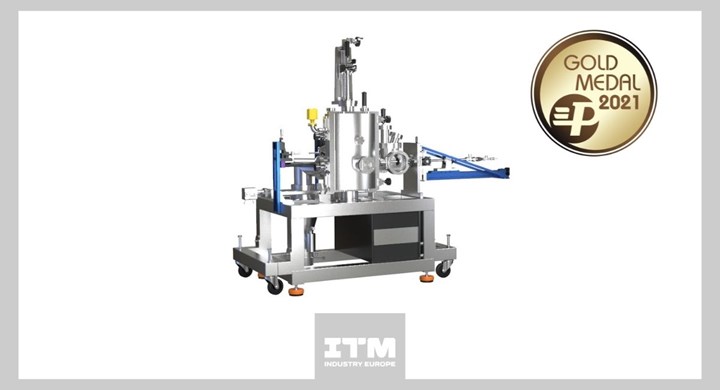

A mobile stand for testing the properties of liquid metals, alloys, glasses, slags and other substances in a wide range of melting points.

Faculty od Foundry Engineering AGH University of Science and Technology, MeasLine sp. z o.o., Aleksander Krupkowski Institute of Metallurgy and Materials Science of the Polish Academy of Sciences

Compare to global solutions, the submitted stand stands out in plus in world practice, because its parameters exceed the levels achieved so far. The mobility of the stand enables testing wherever there are conditions for extending the scope of tests to include supplementary ones. The degree of use of innovative solutions is wide, and the planned unique design solutions not only improve the determination of the contact angle and surface tension, but also many other important material characteristics. The stand has important and unique operating values, proven in previous proprietary solutions of this type. The device was created as part of a project financed by the National Science Centre.

Metal-diamond tools without the use of critical materials for the treatment of concrete and stone surfaces

Łukasiewicz Research Network – Krakow Institute of Technology

Offering innovative metal-diamond tools on the market causes a significant change in terms of the following parameters: • the cost of producing tools based on the developed materials is about 60% of the cost of producing them using commercial materials; • reducing the risk of cancer in toolmaking workers by eliminating Co; • increasing the efficiency and durability of tools by modifying the phase composition of the matrix.

A prototype line for the production of burgers from vegetable outgrades

Łukasiewicz Research Network − Industrial Institute of Agricultural Engineering

The line was created as part of a project whose main goal was to develop an innovative method of calculating the carbon footprint for the production process of burgers made from post-production waste in plants that freeze vegetables. Waste management technology allows to reduce the waste of natural resources and the negative impact of food production on the environment.

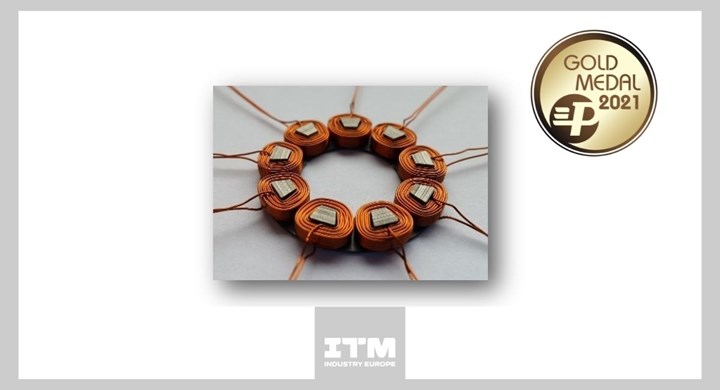

Soft magnetic core of a brushless DC electric motor with low power permanent magnets.

Łukasiewicz Research Network − Institute of Non-Ferrous Metals

The soft magnetic core with a hybrid structure allows to ensure the lowest possible power losses in it, with its small dimensions and low weight. This solution can be used in modern devices, where the miniaturisation of the drive system and energy efficiency play an important role. The hybrid core was used in the stator of the RH ROT heart support pump developed by the Professor Zbigniew Religa Foundation for the Development of Cardiac Surgery in Zabrze.

SHP ND-PNWE-AE

AEP Rybicki Zwada Sp.J./ AJAN Polska

The SHP260 ND-PNWE-AE plasma cutter is an advanced device designed for cutting steel with a plasma arc. The uniqueness of the SHP260 cutter lies in the fact that it is made in 94% by AJAN ELEKTRONIK and not assembled from generally available components. The knowledge that the company has at its disposal contributed to the continuous development of this technology, and its latest version (SHP260 ND-PNWE-AE) already has constant visual supervision over the wear of the most important components of the machine. This supervision takes place online or offline and contributes to increasing productivity (on average by 7%) and reducing direct and indirect costs. The amount of savings depends on the individual analysis of cutting costs that AJAN POLSKA can perform for the interested person. Exemplary calculations are presented in the “campaign regarding consumable parts” available at www.ajanpolska.pl/kopalnia-wiedzy/. We encourage you to familiarise yourself with the offer of AJAN POLSKA and to visit our stand in hall 5 during the ITM 2021 fair, where the abovementioned cutter will be presented.

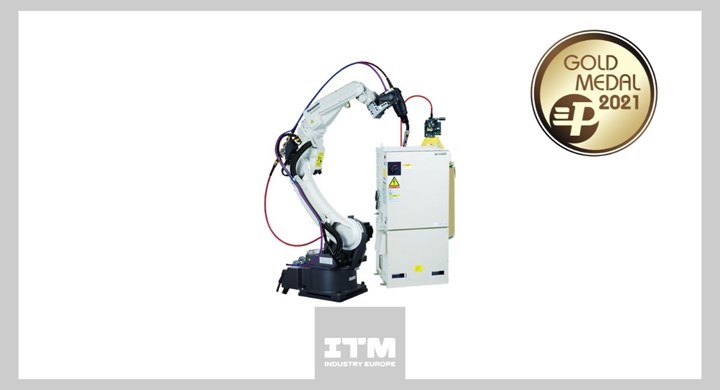

TAWERS SUPER ACTIVE WIRE ALUMINUM system with PULS STICH function

PANASONIC ROBOT AND WELDING SYSTEMS EUROPE A DIVISION OF PANASONIC INDUSTRY EUROPE GmbH / TECHNIKA SPAWALNICZA Sp. z o.o.

“Robotic welding system with active wire feeding with the PULS STICH function that allows to achieve very high quality welds when welding aluminum and its alloys. This feature allows you to achieve high-quality TIG welding at significantly higher speeds (up to 1.8 m/min.) while maintaining process stability. The TAWERS SUPER ACTIVE WIRE ALUMINIUM system with the PULS STICH function is widely used in welding products that require high quality and aesthetics of joints, such as aluminium bicycle frames, tanks, scaffolding, stairs and many others.”

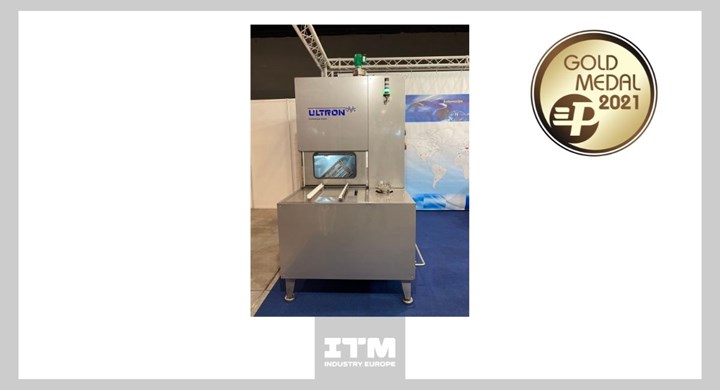

UN-500M 3D PRINTER spray-ultrasonic chamber washer with a rotating basket

ULTRON Zakład Urządzeń Elektronicznych Krzysztof Krankowski

UN-500M 3D PRINTER is a modern ultrasonic spray washer designed for washing workpieces in water solutions. The innovative system of high pressure and several frequencies of ultrasound with submerged liquid flow ensures the highest level of cleanliness in the shortest time. The process basket may rotate or swing. The device performs washing, rinsing and drying procedures. The process is fully automatic and configurable from the driver. Advanced systems extend the life of the bath and minimise electricity consumption.

MODERNLOG 2021

ALVO® Ultra V-bot − mobile UV-C disinfecting robot

PPH Wobit s.c. E.K.J. Ober

The ALVO® Ultra V-bot is a mobile UV-C disinfecting robot that provides a high-quality decontamination process, facilitating the creation and implementation of more accurate hygiene plans in various locations, not only in hospitals. The ALVO® Ultra V-bot uses the UV-C light technology, which destroys the nucleic acid (DNA) of dangerous pathogens, including SARS-CoV-2. Decontamination is remotely controlled and the robot can work autonomously after programming.